News

Electric forklifts have become essential tools in various industries, from warehouses to manufacturing plants. These electrically powered machines are not only eco-friendly but also efficient and cost-effective. One critical component of an electric forklift is its battery, which plays a crucial role in powering the vehicle. In this article, we will delve into the world of electric forklift batteries and answer the question, "How many volts is an electric forklift battery?"

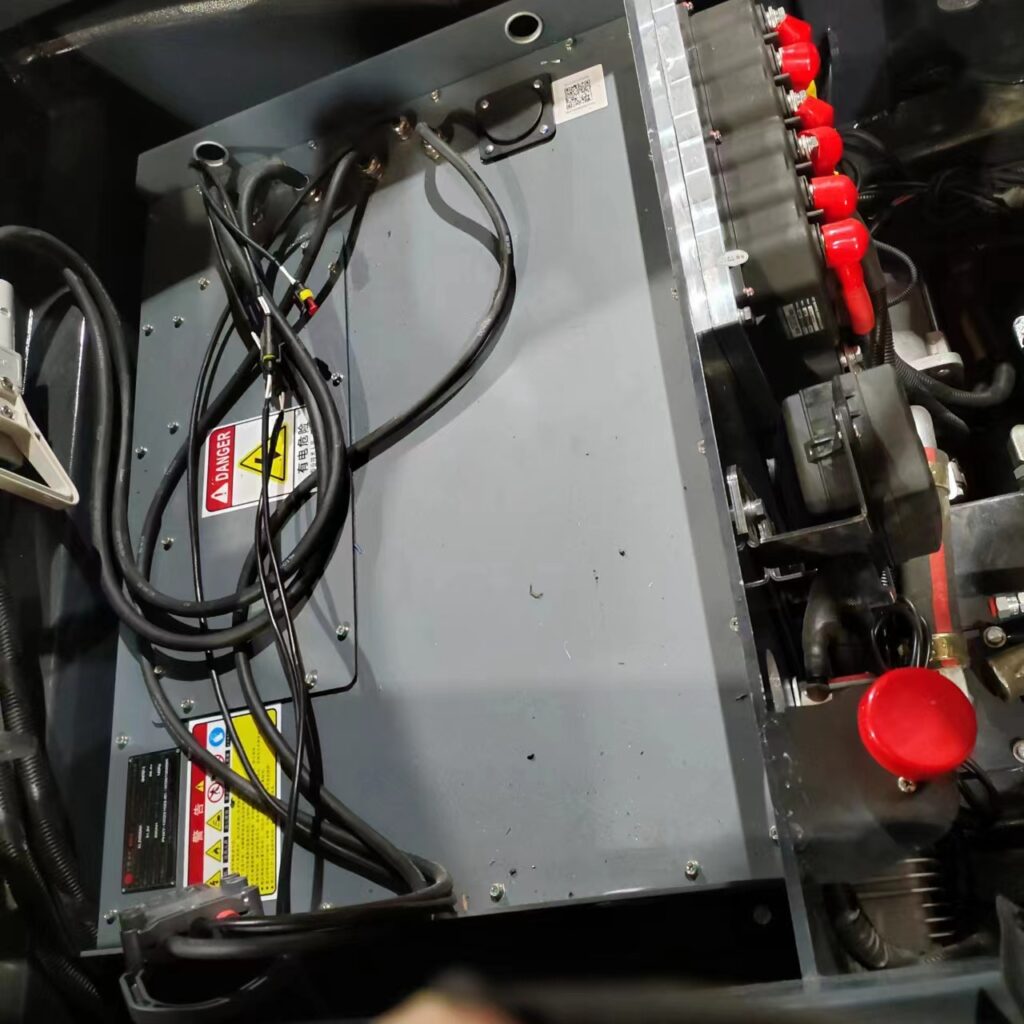

Before we dive into the specifics of voltage, let's begin by understanding electric forklift batteries. Electric forklifts, unlike their traditional counterparts that run on internal combustion engines, rely on rechargeable batteries for power. These batteries are usually lead-acid or lithium-ion, and they come in various sizes and configurations to suit the requirements of different forklift models and applications.

Electric forklift batteries are designed to provide the necessary energy to propel the forklift and operate its lifting mechanisms. The voltage of the battery is a crucial factor in determining the performance and capabilities of the forklift.

Voltage, often measured in volts (V), represents the electrical potential difference between two points in an electric circuit. In the context of electric forklifts, voltage plays a significant role in determining the power output and overall performance of the vehicle. The voltage of an electric forklift battery can vary based on several factors, including the type of forklift and its intended use.

Electric forklift batteries typically have a voltage range that varies from 24 volts to 96 volts. The choice of voltage largely depends on the size and capacity of the forklift and the specific application it is designed for.

24-Volt Batteries: These batteries are common in smaller electric forklifts used in light-duty applications, such as in warehouses or retail settings. They provide sufficient power for lifting and transporting loads in confined spaces and are often maneuverable and compact.

36-Volt Batteries: Electric forklifts equipped with 36-volt batteries are more versatile and can handle a broader range of tasks. These forklifts are commonly used in medium-duty applications, such as distribution centers and manufacturing facilities.

48-Volt Batteries: Forklifts with 48-volt batteries offer even more power and are suitable for heavy-duty applications. These forklifts can handle larger loads and are often used in demanding industrial settings, including construction sites and large warehouses.

72-Volt and 80-Volt Batteries: These higher voltage batteries are typically found in large electric forklifts designed for heavy industrial use. They offer exceptional power and are capable of handling extremely heavy loads and operating for extended periods without recharging.

96-Volt Batteries: Electric forklifts with 96-volt batteries are at the top end of the voltage spectrum. These forklifts are designed for the most demanding applications, such as ports, shipping yards, and other heavy-duty environments where maximum power and endurance are required.

Several factors influence the choice of voltage for an electric forklift:

Load Capacity: The weight of the loads the forklift will be handling is a crucial consideration. Heavier loads require a higher voltage to provide the necessary power for lifting and transporting them efficiently.

Operating Environment: The specific working conditions, including space constraints and terrain, can affect the choice of voltage. In confined spaces, lower voltage forklifts may be preferred, while rough outdoor terrains may require higher voltage for better performance.

Duty Cycle: The frequency and duration of usage impact the choice of voltage. Forklifts used for extended periods without frequent recharging may benefit from higher-voltage batteries.

Budget: The cost of the forklift and its battery is also a significant factor. Higher voltage forklifts tend to be more expensive, so budget constraints may influence the choice of voltage.

In conclusion, the voltage of an electric forklift battery varies depending on the forklift's size, intended use, and application requirements. Understanding these factors is essential when selecting the right electric forklift for your specific needs. Whether you're operating in a warehouse, a distribution center, or a heavy industrial setting, the right voltage ensures that your electric forklift performs efficiently and effectively, making your operations smoother and more productive.

Electric forklifts are a testament to the advancements in electric vehicle technology and their growing importance in modern industrial equipment. As technology continues to evolve, we can expect even more innovations in electric forklift design and battery technology, further enhancing their performance, sustainability, and economic advantages for various industries.